What We Deliver

Gear Manufacturing

High-precision gears produced in-house ranging from small precision gears to large industrial gearsets, all made to DIN standards.

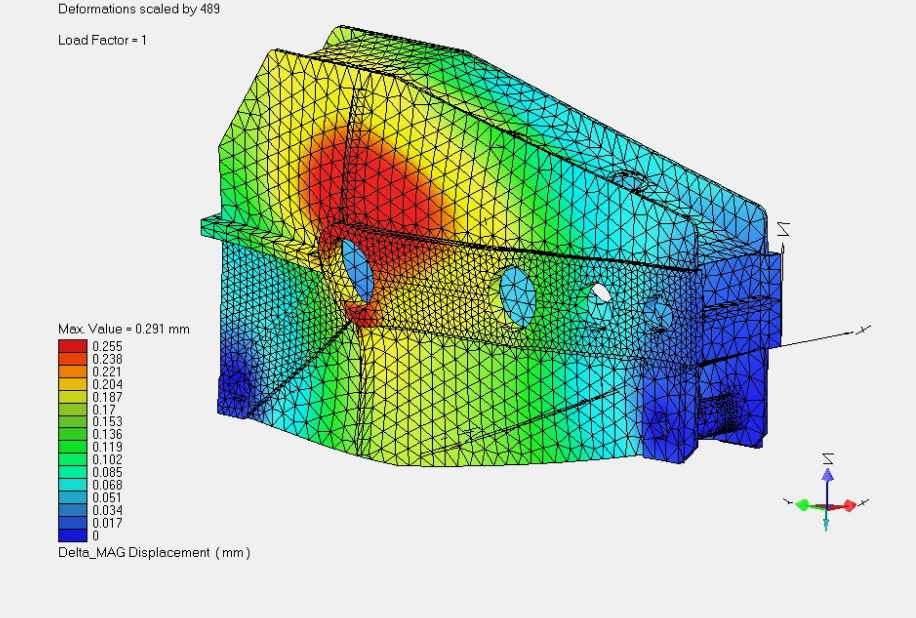

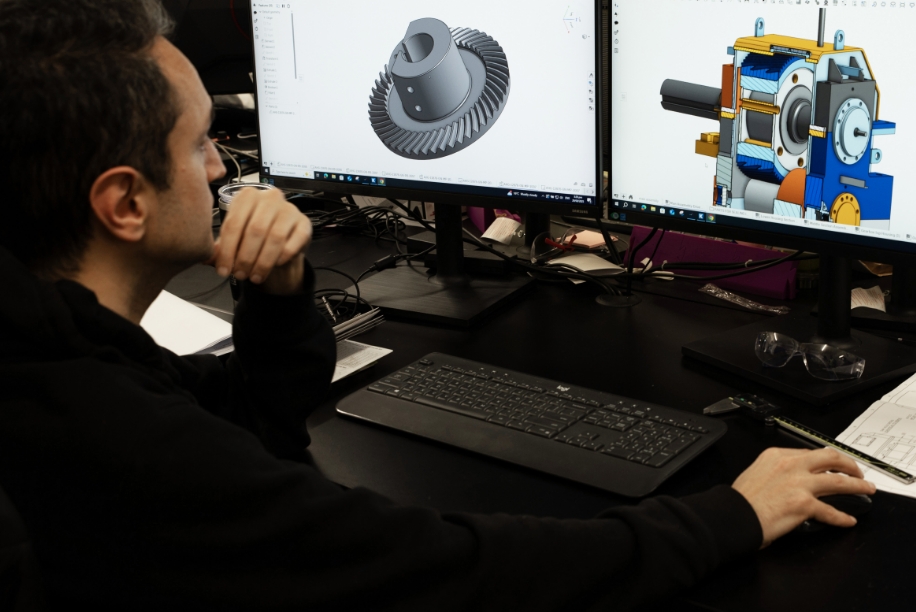

Gearbox Design & Engineering

Simulation-driven gearbox design using advanced CAD and analysis software, manufactured to ISO 9001 standards.

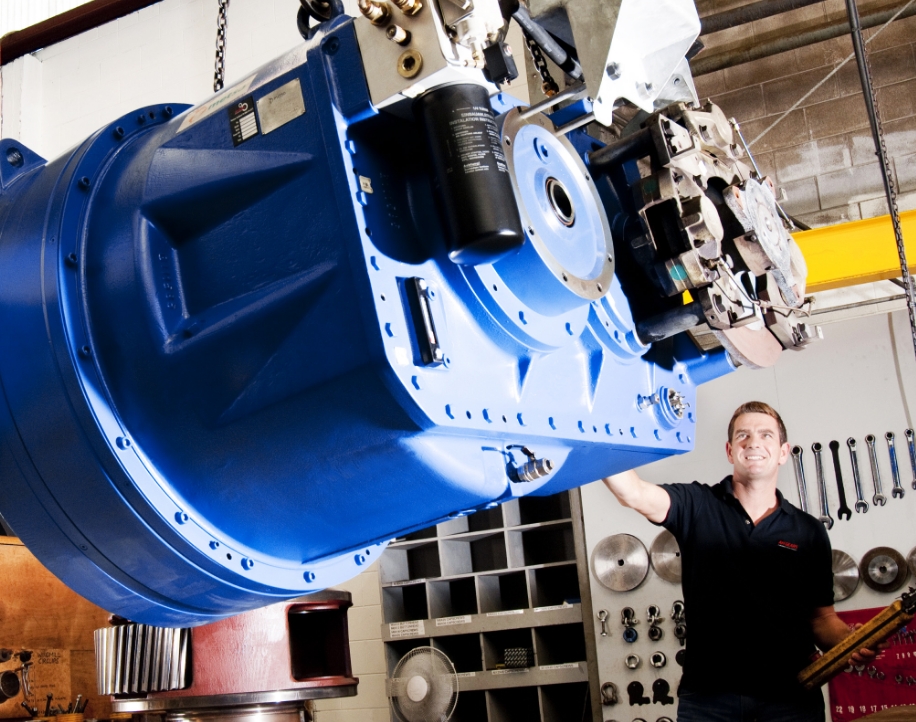

On-Site/ In-House Service & Repairs

Rapid inspection, maintenance, and repair of gearboxes on-site or in our workshop, including shutdown support, rebuilds, and component upgrades.

Reverse Engineering & Upgrades

Worn or obsolete parts recreated, strengthened, and improved through reverse-engineering and analysis to extend equipment life.

Quality Inspection & Testing

Micron-level gear measurement using GMM and CMM equipment with certified reports, root-cause analysis, and condition monitoring to ensure reliability.

Your Challenges. Solved.

Keep Your Plant Running

When equipment stops, productivity does too. We respond quickly on-site and provide full support to get you running again.

Re-manufacture of Obsolete or Custom Components

Older or unique parts can be hard to replace. We reverse-engineer and upgrade them to modern standards to extend service life.

High Quality Standards

Inconsistent tolerances and finishes in gears can cause vibration and wear. Our precision manufacturing and inspection processes produce high quality components for mission-critical applications.

Short & Reliable Lead Times

We control design and manufacturing in-house to shorten delivery cycles and maintain schedule certainty.

Supporting the Industries That Keep the World Moving

With expertise across high-performance, industrial, and energy sectors, AH Gears provides trusted solutions that keep mission-critical systems operating reliably.

Energy & Renewables

Steel & Heavy Manufacturing

Pulp & Paper

Mining & Quarrying

Marine & Offshore

Industrial Processing

High Performance Automotive

Aviation

Precision Manufacturing

Built and manufactured to ISO 9001 standards.

End-to-End Engineering

Design, simulation, and custom solutions for gear and gearbox systems.

Service & Reliability

On-site servicing, component upgrades, and condition monitoring to reduce downtime.